Crafts and Industry

Jeweller's and Watchmakers Tools On the top left is a jeweller's scales and some weights. The scales were used for measuring gold and silver. The jeweller had to hold the scales by the strings. On the bottom left is a watchmaker's vice. The larger vice on the right is a jeweller's vice. On the bottom is the head of a jeweller's hammer. The head is about four centimetres long.

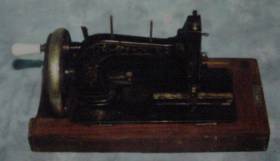

Sewing Machines

This sewing machine (left) is a singer sewing machine. The instruction booklet with it, is dated 1920. It is still in working order. The other two sewing machines are even older.

Source: Mary Maher, Dennis Hamilton & Kieran Costelloe.

Miner's Picks

These are pointed picks used by Coal Miners. The bottom one is very old and

had an iron sleeve over the top to hold the handle.

Source: Richard Eyre.

Wheel Wright's Tools

Wheel Wrights made wooden wheels for horse's carts. This work was also sometimes

done by a blacksmith. These are some of the tools used in wheelmaking:

From Left:

Dividers for measuring length; Wood-turner's chisel for shaping timber; Adze

which was used for shaping timber; Callipers for measuring the width of wheel

hubs; Spoke-shave which was used for shaving small pieces from timber; Travellers

which was used like a trundle-wheel for measuring circumference of wheel rims.

Tallis' Forge

The forge that was in Freshford was owned by Paddy Tallis. On the left side of the picture lies a mill stone, it was used for binding cart wheels. On the left side of the forge there is a frame to which a wheel was attached. There was a belt from the wheel to a fan which propelled air round the circumference of the mill stone. Lighted coals were brought from inside the forge. It then would be fanned by turning the wheel which we referred to earlier. Dry saw dust would also be placed on top of the coals which would increase the temperature of the iron enlarging it to a greater size than the wheel that was to be bound.

Achieving this, the blacksmith and his assistant would raise the band with two pairs of tongs from the glowing fire striking it with a blow of a hammer to remove fire debris from the band and placing it carefully over the waiting cart wheel. They tapped it into place with great speed. They would stand the lighting wheel up and roll it with great haste into the river to cool it.

In the forge, there was a bellows, a vice, an anvil, and other tools such as

hammers and chisels.

Tallis' Forge Sources:

Large Photograph: Pat Tallis.

Small Photographs: "We grew up around Freshford".

Last

This is a cobbler's last. It was designed so different size shoes could be

fitted over it. At that time, many people mended their own shoes or boots. The

soles of shoes were attached with small nails or tacks called "brads". The last

was steady on the ground or table, no matter which way ti was left down.

Source: Veronica Doheny.

Durrow Bricks

These two bricks were made near Durrow around the beginning of the century. The one on the left has the word "Tinweir" stamped on it. The one on the right has the word "Durrow" stamped on it. The clay for the bricks was got at Tinweir and was taken by buckets carried on overhead cables, to Attanagh, where bricks were made.

Johnny Ivory, Ballyconra remembers the buckets passing over the main Durrow-Ballyragget

road and the river Nore near the Tallyno Bridge.

Source: Tony Coady.

Staunton's Mill

Mariea Roma was the first registered owner that we are aware of. The Maher family acquired the mill as part of the estate of Upper Court Manor, which they had purchased and later sold. The Maher family are still Landlords of a great part of Freshford. The next two owners of the mill were Edward Staunton and his son Jack. Then Tony Tallis bought the mill.

The millwheel stopped operating in 1972. The mill fell into disrepair and it was burnt to a state where it had to be demolished for safety reasons.

Carpenter's Tools

These tools were used by carpenters 100 years ago. They are all made from beech.

On the left is a "Box Plane". The large plane on the right is called a "Jack

Plane". The one in the centre is called an awl. The handle was hollow, and the

top could be unscrewed to hold the needles. The awl was used for making holes

in leather or timber for small nails (called brads).

Source: Kieran Costelloe.

These

are other carpenter's tools from around the same time. On the left is a saw-set

which was used for setting the angle for the teeth on the saw. In the centre

is a spook-shave which was used for plaining off curved pieces of timber. On

the right is a clamp which was used for measuring strips of timber to be cut

out for inlaying furniture.

These

are other carpenter's tools from around the same time. On the left is a saw-set

which was used for setting the angle for the teeth on the saw. In the centre

is a spook-shave which was used for plaining off curved pieces of timber. On

the right is a clamp which was used for measuring strips of timber to be cut

out for inlaying furniture.

Source: Kieran Costelloe.

Moulding Planes

This is a selection of Moulding Planes used to design furniture moulding or

window frames. All, except the top one, are made of beech wood. The top one

is made of box-wood.

Source: Kieran Costelloe.

Selection of Craftsmen's Tools

This is a selection of tools used by different craftsmen. From left to right: Augurs: The Augurs were used for boring holes in timber. Slaters Hammer: This was used for fixing and breaking slates. Hat Set (2): These hammers were used for cutting lengths of iron to make horseshoes. It had a very sharp end. A blacksmith used the hammer. Pointed Hammer: This may have been used to drive railway spikes.

Local Dentist

Michael Fitzpatrick lived in a two-roomed thatched house in Blackwood. He practised dentistry from about 1840 to his death in the 1880s. He had a set of instruments for drawing teeth. All patients had their teeth pulled without anaesthetic. There was no mention of whiskey before or after the procedure. His practice was widespread. Michael Fitzpatrick is buried in the Old Freshford Cemetery at the Protestant Church. The instrumetns were given to Dr. Hourigan a medical doctor in Freshford after his death, by his son Jer. They were spanking when handed over. Jer's was the local rambling house. It was not unusual to have between 20 and 30 people there each evening. It was also the local card school. Most people sat on the bank opposite the house, there was no room to get in.