Cam chain (timing chain).

_______________________________________________________________________________________________

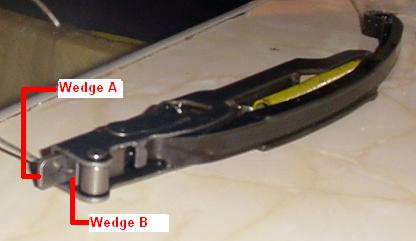

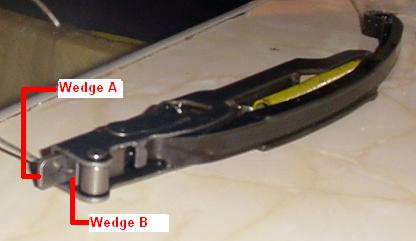

Cam chain tensioner blade.

The tensioner blade is made up of a spring metal blade coated in rubber and a spring.

The side of the tensioner that bolts onto the cylinder head is the "rear" of the tensioner.

The side of the tensioner with the rubber blade is the "front" of the tensioner.

The top of the tensioner has two wedges in it.

The rear wedge is called "wedge A"

The front wedge is called "wedge B"

To release tension from the cam chain push wedge B down and then pull wedge

A up. Insert a 2mm pin into the hole in wedge A to prevent it slipping back down.

There is a risk that the 2mm pin may fall down into the engine so use a long

pin and bend a large loop onto the end of it so it won't fit into the engine.

If wedge A has recessed so far into the tensioner body that you can't lock a vice

grip onto it then the chain is worn. To grip onto the wedge, gently insert a

long screw driver or something down between the chain and the tensioner blade

while pushing down wedge B, this will cause wedge A to rise more.

Also, there is a rubber pad between the rear of the tensioner and the cylinder

head, when removing the tensioner first lousen the bolts, remove the rubber pad

and then remove the bolts and the tensioner.

_______________________________________________________________________________________________

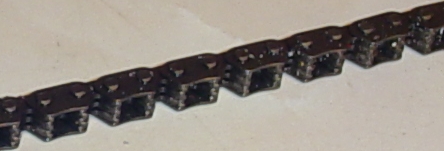

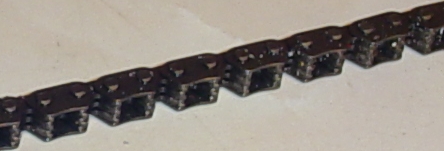

Cam chain.

Silent multi link chain with 1/4" pitch and 118 links.

Honda endless cam chain PN: 14401-MN1-671

DID endless chain (rivet link available): DID SCA-0409A SDH-118LE

Most manufacturers recommend that you fit an endless chain as rivet links are

less reliable than factory links, I believe fitting an endless chain to the

Bros would require crankcase separation.

The rivet links that comes with the DID chain do not have dimples in them,

so it is more difficult to center the riveting pin.

This chain is very easy to split.

Sprockets

I believe silent chains are not as hard on sprockets as roller chains.

__________________________________________________________

Cam chain replacement using a rivet link.

The main difficulty is finding enough room to use the rivet tool.

For the rear cylinder I took the cam sprocket off the cam shaft, this gave

me enough room to use the rivet tool. I also used cable ties to strap the

chain onto the sprocket at various times. Try to get the camshaft with all

cam lobes facing down before removing the last sprocket bolt as this will make

it easier to set valve timing later.

For the front cylinder I removed the cam shaft.

If you are using a chain rivetter that requires less room them you may

not need to remove camshaft etc.

_______________________________________________________________________________________________

Camshaft removal (NT650 HAWK GT).

Remove the cylinder head covers and carbs.

Remove the timing hole cap and crankshaft hole cap from the

left crankcase cover.

Align the FT mark (rear: RT mark) on the flywheel with the

index mark on the left crankcase cover timing hole by turning

the crankshaft counter clockwise.

Make sure the piston is at TDC (Top Dead Center) on the

compression stroke with all the cam lobes facing down.

If the cam lobes are facing up at TDC, turn the crankshaft

360° counter clockwise, and re-align the mark and notch.

Pull wedge A straight up while holding wedge B down.

Secure wedge A with a 2mm pin.

Remove the end cam holder by lousing the bolts in 2-3 steps.

Remove the cam sprocket bolt, rotate the crankshaft counter

clockwise 360° and remove the other bolt.

Note: Be careful not to allow the cam sprocket bolts to

fall down into the crankcase.

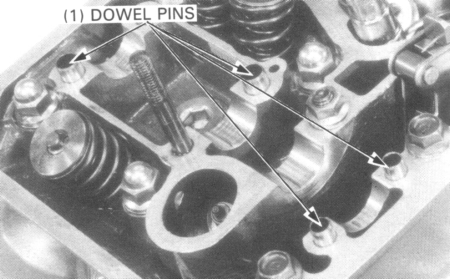

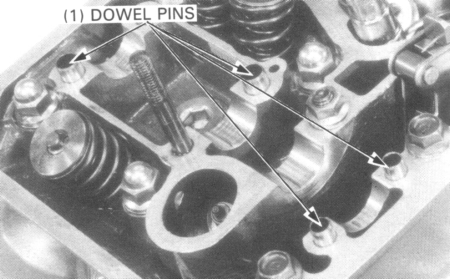

Remove the 3 camshaft holder mounting bolts and the nut

in 2-3 steps and then remove the oil plate and the holder.

Remove the dowel pins.

Hang the cam chain on the camshaft behind the camshaft-

flange and remove the cam sprocket while lifting the camshaft

out.

Attach a piece or wire to the cam chain to prevent it from

being dropped into the crankcase.

_______________________________________________________________________________________________

Installation of cam shaft(s).

The front and rear camshafts are different, do not

confuse them.

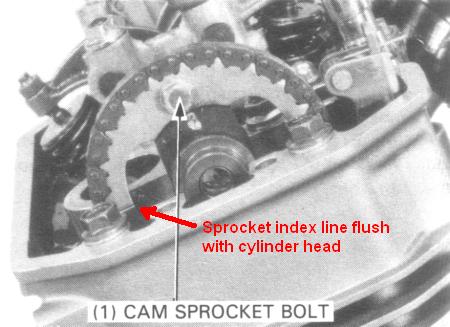

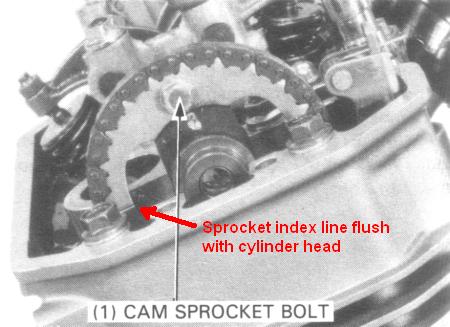

There is an index line on the cam sprockets, when the

flywheel FT or RT mark is aligned, the index line on the

appropriate sprocket should be flush with the top of the

cylinder head.

Usually when all the cam lobes are facing down, all

the rocker arms will have a small amount of jog in them.

_______________________________________________________________________________________________

Front camshaft only.(NT650 HAWK GT)

Turn the crankshaft counter clockwise and align the RT

mark on the flywheel with the index mark on the timing hole.

Make sure the REAR cam lobes are all facing UP. If they are

not, turn the crankshaft counter clockwise one revolution so

that the REAR cam lobes are all facing UP. (NOTE: This is the

valve overlap position.)

Continue turning the crankshaft counter clockwise (128°) until

the FT mark on the flywheel aligns with the index mark on

the timing hole (approx. 3/8 turn).

Install any necessary dowel pins.

Grease cam lobes and journals.

Install the camshaft in the cylinder head through the cam chain

and install the cam sprocket on the camshaft.

With the cam lobes all facing down, align the timing marks

(index lines) on the cam sprocket with the top of the cylinder

head.

Place the cam chain on the sprocket.

Install the cam sprocket on the camshaft flange and recheck

that the timing marks (index lines) align with the top of the

cylinder head.

Inspect valve clearance.

Align the cam sprocket bolt holes in the cam sprocket and

Align the cam sprocket bolt holes in the cam sprocket and

camshaft, install and tighten the cam sprocket bolt.

TORQUE: 23 Nm.

Install the holder, oil plate, 8 mm bolts, 8 mm nut and 6 mm

bolts.

TORQUE:

8 mm bolt: 23 Nm

8 mm nut: 23 Nm

6 mm bolt: 10 Nm

Turn the crankshaft counter clockwise 360° and install the

other sprocket bolt.

Install the end holder.

CAUTION

Note the direction of the camshaft end holder, install the flat

surface on the holder facing in.

_______________________________________________________________________________________________

Rear camshaft only.(NT650 HAWK GT)

Turn the crankshaft counter clockwise and align the FT

mark on the flywheel with the index mark on the timing hole.

Make sure the FRONT cam lobes are all facing down. If they

are not, turn the crankshaft counterclockwise one revolution

so that the FRONT cam lobes are all facing down.

Continue turning the crankshaft counter clockwise (232°) until

the RT mark on the flywheel aligns with the index mark on

the timing hole (approx. 5/8 turn).

Place the camshaft into the correct position with the cam lobes all

facing down.

Install the cam sprocket and camshaft holders using the same

procedure as for the front cylinder.

Inspect valve clearance.

_______________________________________________________________________________________________

Front and rear camshafts.(NT650 HAWK GT)

Turn the crankshaft counter clockwise and align the FT

mark on the flywheel with the index mark on the timing hole.

Install the front camshaft with all the cam lobes facing DOWN.

Align the index marks on the cam sprocket with the top of the

cylinder head.

Continue turning the crankshaft counter clockwise (232°) until

the RT mark of the flywheel aligns with the index mark on

the timing hole (approx. 5/8 turn).

Install the rear camshaft with all the cam lobes facing DOWN.

Align the index lines on the cam sprocket with the top of the

cylinder head

Remove the 2mm pins holding the tensioner wedges.

Note:

Be careful not to let the 2mm pin fall into the crankcase.

Do not forget to remove the 2mm pin.

Inspect valve clearance.

Align the cam sprocket bolt holes in the cam sprocket and

Align the cam sprocket bolt holes in the cam sprocket and