Front brake caliper rebuild.

CAUTION

- Under no circumstances should you do anything that might scratch or

damage the finish on the pistons in any way. (Don't try to pull the pistons

out with a pliers).

- Use only DOT 4 brake fluid as anything else may cause brake failure.

- DOT 4 brake fluid is hydroscorpic which means it absorbs water,

thus you should only use brake fluid from a sealed container

- Do not allow foreign material to enter the master cylinder resevoir

while filling it.

- Brake fluid can damage paint, plastic and rubber.

- Hydraulic brakes should only be serviced by a trained and expierienced

person.

- If the brakes are "spongy", leaking or have any defects whatsoever

then the motorcycle is not safe to drive.

- If brake fluid or and other substance contaminates the brake disc

then it will need to be cleaned with "brake parts degreaser".

- If brake pads become contaminated with brake fluid or any other

substance then they should be discarded.

- Do not mix different types of brake fluid.

- After servicing the brakes: inspect and test the brakes before taking

the bike on the road.

- If any of the threaded components (eg: caliper body bolts, bleed

nipple, hose connection etc) are damaged then the front brake system is

unreliable.

- Do not bend or twist the brake hose (Inspect the hose for cracks or

any signs of damage).

- Do not hang the caliper off the brake hose.

- Do not apply grease on the friction surface of the brake pads.

- Do not apply an excessive amount of grease on the back of the brake pads

as it might creep onto the friction surface of the pads or disc.

- Brake dust may contain asbestos fibres that can and will cause

diseases such as CANCER.

- Take whatever steps are necessary to avoid inhaling brake dust (Never

use an air brush).

- If you use compressed air to push out the pistons then the pistons

will shoot out like bullets.

- Keep the caliper on or wrapped in a towel to prevent scratching

it.

WHAT YOU NEED

- The usual tool: spanners, allen keys etc.

- A full set of "piston seals" and "dust seals" and two "joint seals".

- 500ml of DOT 4 brake fluid and brake bleeder equipment.

- An "E12 female torx socket", usually comes in 3/8" drive.

- Air compressor or "motorcycle brake caliper piston removal tool".

- Red rubber grease, I find that red rubber grease dries out after

a few days so I mix a small amount of brake fluid thru it so it stay

wet a little longer

- You may need new pistons, the J model bros has different pistons to

the K and L bros, They are basicly the same piston but the J model piston

accepts a "piston cap", Honda no longer manufacture the J model piston, it

has been superseded to the K-L piston. The dimensions of the J model

pistons are as followes:

Large piston:

- Diameter: 31.948 mm - 31.998 mm, service limit: 31.94 mm

- Length (without cap): 23.5mm

- Length (with cap): 25mm

Small piston:

- Diameter: 30.148 mm - 30.198 mm, service limit: 30.14 mm

- Length (without cap): 23.5mm

- Length (with cap): 25mm

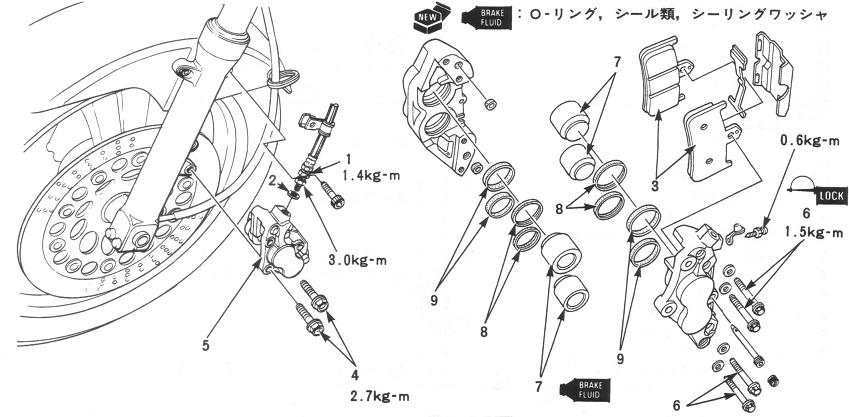

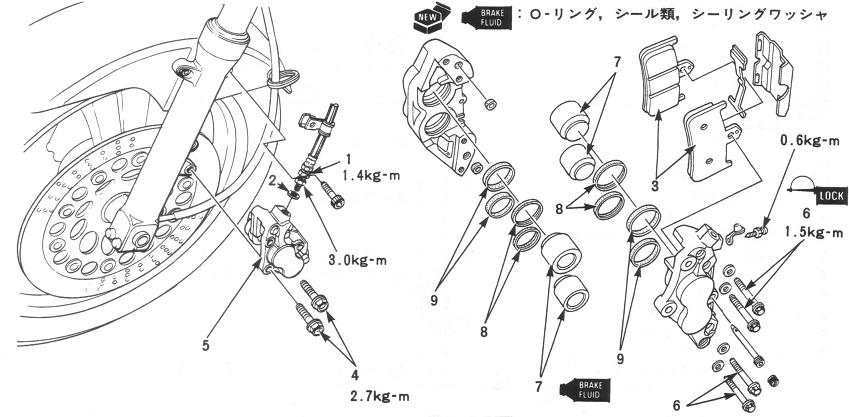

PROCEDURE.

- Swing the brake caliper off the disc.

- Using the brake lever, pump out the caliper pistons as far as you can

without ejecting the pistons from the caliper.

- Disconnect the brake hose from the caliper and bring it to your work

bench.

- Position the hose so that it doesn't leak.

- Remove the plug, pin, spring pad and brake pads.

- Using an "E12 female torx socket" remove the four caliper body bolt

in a criss cross pattern in 2 or 3 steps.

Note: If thread locker was used on the bolts last time it may be difficult to

remove the bolts.

- Seperate the 2 parts of the caliper body and remove the 2 joint seals

(rubber washers).

- To remove the pistons for the caliper body, you can use

a "caliper piston romoval tool" or you can use compressed air. I used

compressed air, when the pistons release they will shoot out like bullets

so wrap the caliper in a towel and place it in a vice so that the jaws of

the vice will stop the piston from shooting out. Invariablely one piston

will come out easier that other so close the vice enough to prevent that

piston from fully ejecting from the caliper, this will allow the compressed

air to push out the other piston. Apply compressed air to one of the ports

while sealing the the other ports, the piston should now come out.

If you are dealing with frozen pistons then you will need the Laser

brake piston removal kit. Applying heat with a blow torch might help

the pistons come out a little easier. The J model piston can be tapped

with a M16 to help pull it out.

- If you are reusing the pistons you must clean them, then completely

remove any cleaner residues.

- If there is pitting on the nickel then the piston should be replaced

but if thats not possible then remove and sharp edges that might damage the seals.

- Use a small pick to pull out the old seals, be carefull not to scratch

the caliper as that would cause a disaterous leak later

- Gently clean out any dirt from where the seals are fitted with fresh

brake fluid. If there is severe corrosion inside the seal groves

then you will have to remove it with a pick and small rotary wire

brush. If the seal groove is full of corrosion then the anodised layer

has failed so you dont really need to worry about damaging it.

- Liberally coat each new seal in special grease

- After the seals are fitted coat the them in special grease

- Coat the sides and edges of each piston with special

grease) and install it by pushing it in, if you push the piston in at an

angle you might nick one of the new seals, push the piston in straight and

gently.

- Fit new joint seals and check that the metal that the seals touch is

smooth and clean.

- Apply "thread locker/sealer" or "copper grease/anti-sieze compound" to

the threads of the caliper body bolts (Honda reccomend thread locker).

- Install the bolts and tighten them in a criss cross pattern in 2 or 3 steps,

- Honda recomend tightening the bolts to 15 Nm when thread locker is used,

however, if threadlocker is not used then a higher torque of 23 Nm might be

justified.