Legging It!

Fitting

Robart Dummy Oleo Legs to your Model?

Allow Gerard to take you through the proceedure as painlessly as possible...

Robart scale landing gear 'strut covers' have been available for ages but I must admit that I'd never given 'em much attention up until the recent past. The latest 'Feeney Flier' most definitely demanded disguised piano wire undercarriage legs however, and these Stateside items seemed the ideal choice. Although not specifically reproducing any full-size aircraft legs in particular, they are eminently suitable for dressing up sport-scale 'lightplane' and 'fighter' designs, and with a bit of TLC they can look most realistic. They certainly transformed the (fixed) 'alighting gear' of my Top Flite Beechcraft 'Bonanza' no end, I must say.

Leg Pulling

The

basic oleo 'facade' components arrive poly-bagged on a sprue, Airfix fashion,

ready to be stuck together. The (injection?) moulding quality is pretty

darn crisp but, as always, it's a good idea to separate the individual

pieces carefully, making sure that all sprue 'attachment points' and surplus

flashing are removed cleanly. A very sharp Number 11 scalpel or keen single-edge

razor blade are both ideal plastic incising/cleaning-up tools in the pre-assembly

preparation routine. It's also prudent to dry-assemble the oleo units

over the model's wire legs just to precisely ascertain the component fits

- and to see if any 'non-standard' cutting/trimming is needed. If trimming

is required, it'll most likely involve shortening the actual vertical

oleo tube height to suit short wire legs. This is easily done with a razor

saw, followed by fine-sanding to clean up the plastic edge prior to eventually

closing the oleo tops with the capping pieces provided.

When sanding the plastic material, either after component sprue separation

or after oleo unit assembly, use fine grade wet 'n' dry paper (used either

wet or dry!) in the 350-800 grit range. Paper grades coarser than this

will cause the plastic to become 'hairy' rather than actually smoothing

it.

The Leg Bone connected to.....

The oleo units are comprised of six principle parts. Each main upright leg is split vertically; these half-shells encapsulate the wire leg from either side with the actual joint lines facing the front and rear. The oleo circular wheel bases are pre-drilled to allow the wire axle to poke through; the holes may need enlarging to suit larger gauge wire legs. The oleo halves partially clasp together by means of tiny pre-moulded male/female studs located inside each triangular 'torque-link' projection; these snap-keepers are backed up by teeny-weeny machine screws going through the circular axle bases, which are then hidden by dummy capping discs. The dummy capping discs locate using a push-fit action on the oleo axle base opposite the fitted wheel. The hollow wing- (or fuselage-) facing oleo tubes are blocked off by neat cups/caps after a 'retaining ring' has been slipped halfway down the oleo leg to stabilise the assembled component. It would almost be possible to leave the units dry-fitted only, but ideally they should be properly glued together…

Sole Mate!

Oleo

fitting and assembly goes like this: First, accurately finalise the basic

fitting of the model's wire legs in place on the airframe using saddle

clamps, minus the dummy oleos. Remove the legs again to fit the oleos

before final leg attachment takes place. Feed the wire axle through the

respective half-shell base first, ensuring the wire fits the vertical

half-groove snugly at the same time. If the base hole needs enlarging,

ensure that it's just big enough to allow a smooth axle penetration; a

drill bit followed by a round file (or glass-paper wrapped around a 1/8"

hardwood dowel) is useful for this work. Now, the other half-shell is

coaxed into place. Because of the pre-moulded locator pegs, a fairly accurate

'snap-fit' of the two oleo halves is easily achieved. At this stage, the

alignment ring and wing/fuselage-meeting end cap parts are test-fitted

again. With wing-mounted wire legs, you may need to enlarge the oleo end

cap hole slightly to enable it to slide around the various sharp bends.

I managed okay though 'as per' - on the Bonanza, at least.

When all fits are deemed satisfactory, the end cap and alignment ring

are removed again; now it's time to permanently join those main oleo halves

in-situ on the wire leg. This can be done by simply wicking thin cyano

into the joint lines using a pointy applicator tip - or glue can be applied

(Airfix-fashion again) to the separated half-shell joining flanges before

pressing accurately together. I've tried both gluing methods and slightly

prefer the 'wicking' approach because the half-shell alignment can be

pre-tweaked in this instance. The disadvantage with the cyano wicking

method is that some areas of the half-shell contact are tighter than others

resulting in patchy cyano penetration. The 'glue then bring together'

approach could lead to mildly misaligned parts if fast cyano was used;

if trying this 'meeting up' gluing approach, Airfix polystyrene model

cement or slow cyano would be the better gluing choice.

When the oleo shells have been glued together, those axle base fixing

screws can be fully tightened up. I left these screws slightly loose during

gluing to allow for the cyano 'seepage' factor before fully tightening

home - but you could rely on just the screw hold to grip this area with

the glue only applied further up the oleo if you wished.

At this stage, no matter how neatly you've joined the oleo half-shells,

some slight moulding misalignment will be evident - mostly around the

protruding circular flanges. Just trim/fine-sand the proud areas back

to harmonise the lines. I also noticed prominent joint line cracks on

some areas; you could try filling the gaps with 'Elastic Plastic Padding'

or similar 'car body' filler. However, I found all of this stuff fell

out again when dry, so a good fine-sanding using 400-grit glass-paper

on a miniature sanding block and/or impact-glued to thin ply works best

to camouflage the visible joint areas. There is another way of disguising

these cracks - see later.

The alignment ring and end cap bits (left a loose fit on the wire leg

during oleo attachment) are now finally slid one final time into position.

Slip the ring halfway down into place first, followed by the end cap.

These items are very easily glued in-situ with thin cyano.

My legs needed extra clamping with Bulldog clips either side of the triangular

torque arm projections, whilst thin cyano bonded the internal connecting

framework together. Minus clamping, the internal pre-moulded plastic 'ribs'

won't meet up in this area. This ain't serious structurally - but it doesn't

look good!

Final assembly involves cyanoing the 'hub cap' and 'wheel-spacer' discs

in place either side of the oleo base. The hub cap disc (actually positioned

diametrically opposed to the fitted wheel - and not even on the wheel

at all!) could almost be left a friction push-fit - but I preferred to

get fully 'stuck in' for added security! The plastic wheel spacer disc

can be used instead of a metal collet 'twixt oleo base and wheel inside

face, but I also used standard metal collets either side of my installed

wheels out of personal preference.

That's about it with the basic assembly; now comes the decoration…

Fancy Footwork!

It's

best to spray the assembled oleo units using the masked off undercarriage

wires, in conjunction with Bulldog clips, as stabilisers. I employed Flair

'Spectrum' matt dark grey and a few coats saw the units looking much more

solid. I didn't bother with primer and all seems fine - but it would be

no harm to prime the units providing the primer, paint and plastic are

all compatible.

The metallic 'telescopic shock absorber' areas, which are usually bright

chrome on the full-size aircraft, presented the biggest headache to get

right. I started with brushed on Humbrol silver which, being rather old,

went on with a yucky 'textured' finish. Some new stuff, applied with a

small artist's sable, went on a bit better - but I was acutely aware of

this product's non-existent fuel resistance, so one just wasn't happy!

(Any attempt to fuel proof Humbrol silver will turn it into a grey sludge!)

Then one heeded Robart's suggestion to use self-adhesive chrome trim sheet

on these areas. Very nice, but would it be available? Luckily, Flair's

'Aluclad' was…

Foiled Again!

Aluclad

is an ultra-thin self-adhesive foil which, with care (and a clinically

smooth basic airframe finish!), can be used to cover entire 'solid-surface'

model airframes in sections. (I dread to think of the cost, though!) After

an initial brief examination, it seemed ideally suited to the task of

representing the chrome telescoping tubes of full-size aircraft undercarriage

legs - and it sure came to the rescue with the 'Feeney Zone' Bonanza!

Basically, strips the depth of each visible shock absorber section were

cut out using an extremely sharp scalpel. These strips were then tailored

to wrap around the oleo and butt-join at the rear out-of-sight. Placement

is not critical, as the adhesive doesn't grip too severely at first. However,

it's easy to crease the foil by heavy-handed initial removal from its

backing sheet and/or during repositioning attempts on the component being

covered. It's wise to have oodles of foil strips standing by if (when!)

cock-ups occur.

The oleo strips went on quite easily; an alternating pressing motion from

the first (central) contact point around towards the rear butt-joining

'meet-up' point each side worked best for me. Various pieces of scrap

hardwood strip were employed to press the foil all over and especially

into tight corners - it's surprising how well it 'moulds' into the nether

regions one is happy to report! Excess foil is easily cut in-situ with

a very keen Number 11 scalpel blade; tweezers are useful for gripping

and plucking the severed foil offcuts.

I must say, I wish I had 'foiled' these areas right from the start for

a smoother finish - but ya live and learn! I'd strongly advise readers

to simulate these areas using Aluclad or similar; this is best applied

after simply spraying the entire oleo unit in one colour first. The triangular

torque arm projections could then be left in the 'background colour' or

painted silver as I did. Using self-adhesive foil on all the cylindrical

oleo areas would also be possible - doing this would hide those (sanded)

joint-lines more effectively too!

Walk Away!

The assembled/painted oleo units are now ready to go on yer model by finally re-clamping the wire legs in place. Remember, during the initial dry-fitting stage, not to place any retaining saddle clamps too close to the undercarriage vertical 'groundborne' leg as subsequent clamp tightening might cause screwdriver clashing on the oleo unit! Whether your model is a 'serious' scale ship or a fun-scale/sports job, these items will really smarten the aeroplane up. Robart's oleo units are available in 'large' and 'small' sizes and in both 'main' and 'noseleg' format, so you're spoilt for choice. I've just ordered the noseleg version, also for the Bonanza, so one can look forward to yet more exciting leg thrills in due course! Be still, my beating undercart!!!

|

|

|

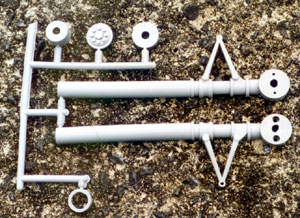

The

various components for Robarts dummy oleo legs, available in assorted

size "main" and "noseleg"

format, arrive nicely presented in poly bags. The bits have been taken out here! |

|

|

|

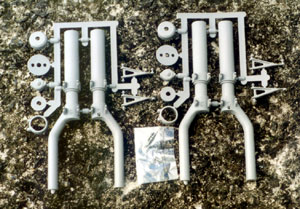

Heres

how the various bits go together. |

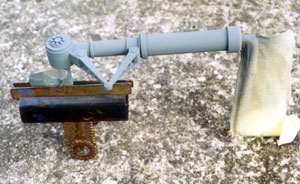

The

assembled leg being sprayed matt dark grey.Note masked off wire.

|

|

|

|

Make

sure the undercarriage wire retaining saddle clamps ain't too close

to the dummy oleos or you could suffer "scratched legs"!

Guess how Feeney found that out?!

|

The

finished oleo on Gerards Top Flight Bonanza certainly looks the

part. Note the Aluclad foil covered areas. Dummy "undercarriage

doors" made from thin ply have since been added to complete

the effect (wheel bay opening is cut from solarfilm)

|