|

|

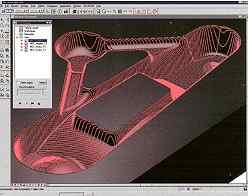

- Solidcam 2000

is a powerful, yet easy-to-use and affordable CAD/CAM Solution

for your Machine Shop. - Provides an integrated solution for Design, 3D Modeling and the CNC-Manufacturing of Parts, with which you can reduce your NC-Programming time and machine downtime. - Enables you to program your parts containing 2.5D features, machine 3D solid and surface models and program your turning parts fast and easily. - Proves that a powerful 3D CAD/CAM System is not necessarily too complex. It can be learned quickly and is an extremely efficient software tool. - Is a native Microsoft Windows application and runs on Standard PCs under Windows95/98 and NT4.0 |

|

New in Solidcam

2000 - Seamless integration of Solidcam with the 3D and 2D design package MicroStation/J Modeler from Bentley - G2/G3 NC-output in Roughing and constant Z-cutting of 3D models. Our post-processors supports Heindenhain dialog style, subroutines and the M-functions of your CNC-machine controller. - Additional options in Linear-finishing: machining can now be performed not only bi-directionally and uni-directionally but also always from the bottom or from the top of the contour. - Spiral and helix approach and retreat in constant-Z milling reduces abrupt changes of the cutting direction and 'witness marks' on the part. - Calculation and G-code generation now available in batch mode. - A new 3D job enables the engraving of profiles and text on surface and solid models. |

|

|

Perfect integration

of CAD and CAM in Solidcam 2000 The CAM Module of Solidcam has been completely integrated with the 3D and 2D CAD package MicroStation/J Modeler from Bentley. Cadtech offers you a customized OEM version of this CAD package, in combination with the CAM-module, at a highly competitive price. For design, editing and manufacturing of models, Solidcam 2000 Modelers also comes with a state-of-the-art surface modeling module which is unique in the mid-range market. |

|

Manufacturers in

particular expect a great deal from 2D drafting and detailing

of drawings. For users, one of the major criteria for a design

package is its performance in 2D drafting and drawing composition

straight from 3D models. Solidcam 2000 uses the Parasolid geometric kernel. Reliable CAD interfaces for processing data in the IGES, DWG, DXF, DGN, STEP, XMT and SAT formats are included. Our users successfully rely on Solidcam as the CAM complement to CAD systems such as a Mechanical Desktop, SolidEdge, SolidWorks, IronCad, Cadkey, CATIA, Unigraphics, Pro/Engineer (and of course Dolphin CAD) etc. |

Automatic 2D drawing composition from 3D models including sections, details, etc... |

|

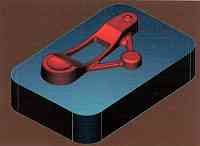

Roughing for

Die and Mould Professionals Iscar has introduced a new unique family of plunging tools that are ideally suited for the machining of deep cavities and shots with high shoulders and with straight or sloped walls. Loads on the machine, tool and workpiece are mainly axial - high bending moments, as in conventional rough machining where very large tool overhangs in deep cavities can be avoided. The die and mold and turbine blade industries can substantially reduce machining cost. Moreover, only a few tools are required for the machining of various complicated shapes and cavities. |

|

Cadtech has, in

close co-operation with Iscar, extended its milling modules so

that all roughing operations now support these new plunging tools.

All positions, where the tools need to plunge are automatically

generated by Solidcam 2000. Roughing with this new plunging method can be applied in standard 2.5D pocketing and on 3D surface and solid models. The plunging options are completely integrated in the standard interface of all Solidcam 2000 jobs. Since the pluging patters and the technology recommended by Iscar have been thorougly implemented in Solidcam 2000, no manual calculations, off-line programming or editing of G-code files are necessary to use these highly efficient tools. |

|

info@dolphin.gb.com