|

Profile of Macsports - Handball Makers - by Michael McGee |

|

Michael McGee took a trip out to Macsports, a Company based in

Bluebell Dublin owned by Gerry MacCormac and his son Ger Og, to learn more

about the process and the people involved in making handballs.

Gerry MacCormac worked as a process controller with the Semperit Tyre Company in Vienna until transferred back to Dublin in 1969 to join Semperit Ireland. In 1982 he left Semperit to set up his own business, Specialised Rubber Components (SRC). The late Joe Lynch R.I.P. the then President of the Irish Handball Council approached the company with a view to producing the 60 x 30 handballs. With the Dunlop plant closing down Ger MacCormac was able to able to transfer the production from Cork to S.R.C. Ltd. The 60 x 30 ball was then made the official playing ball. In 1988 with the supplies of the Spalding ball ceasing which in fact caused the postponement for several months of the Irish handball 40 x 20 championships. SRC were then able to produce the 40 x 20 ball for the Irish Handball Council. Two years research went into it and new features were added. First the ball had a truer flight and it eliminated bone bruises. The 40 x 20 ball then became the official ball in Ireland and was the official ball for the World Championships hosted in Ireland in 1994. Ger was very pleased with the fact it was the first time an Irish made ball was the official ball for the world championships. The Challenger series of handballs was then introduced for the Juveniles and it proved very successful and the fruits of it can be seen today when our Juvenile players are winning World Titles thanks to MacCormac’s Challenger handballs. The MacCormac’s have been making handballs in their premises in Bluebell since 1984. |

| Ger Og explained there are 12 processes to making handballs. First is the raw material which he sources in Malaysia and comes in bales. The first machine is a roll mill which will break down the natural rubber into a processable material. It will eventually turn into a soft gum type product. It is at this stage you add all the ingredients special powders and chemicals. For every rubber product there is a formulation behind it. A basic natural rubber will have sulphur and some activators which then makes it ready for the moulding process. The extruder machine takes the rubber from the two role mill which is heated up to 1 bar of pressure with steam which drives the rubber into a chamber and as the pressure is built up you feed it through a dye head. The dye head is cut out of steel to what ever shape you require the rubber to be in for the next stage. Third stage is called the blank preparation, which is the material fed out from the extruder into a sausage shape, which is sent through a cutting machine to prepare it into a set weight of rubber and a set size that will suit the mould. The cut “slugs” as they are called are stacked into trays where they will be placed into the cavity of the mould and heated up to 150 degrees and 2000 psi pressure for a fixed period of time. What happens in that time is that the sulphur will react and actually bond the rubber together. When the mould closes the rubber will flow into the shape of the cavity into a half ball and during this period knits the material together. The last step in the process is roughening the surface of each half ball then a rubber solution is applied. Gas is then put in and both half balls are joined together and then put into a second mould and heated up to 160 degrees for a fixed period. The rubber solution will bond the two half balls together. They are then sanded automatically 120 handballs at a time. |  |

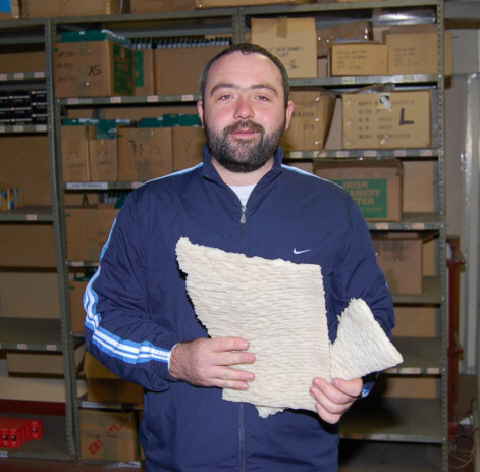

| The product stamp is then placed on the handballs before packaging for the junior handballs, or depressurised in the case for the adult handballs, where the pressurised containers to hold the handballs are sealed. | Ger and Ger Og with their ISO Manufacturing Standard Organisational award for Excellence |

|

With the Courtcraft handball gloves operation ending in Belfast Ger

Og got in touch with former Irish Handball Council President Sean McEntee

regarding distributing of handball gloves. “We always had a great working

relationship with Sean McEntee and Courtcraft. We were able to source the

gloves and that is how Macsports started off said Ger Og.”

Macsports Distribution Company was set up in 2000 and has an extensive product range. Squash balls are mainly exported for Dunlop to the U.S.A. and Canada. Challenger 1, 2, & 3 children’s handballs. Ladies 60 x 30, One Wall and the adults 60 x 30 and 40 x 20. The handballs are not the only products manufactured on the premises. They also do landscaping products for all the major County Councils and Landscapers. Camping equipment during the summer months. For Irish Rail they make shock absorbers, buffers, draw gears rubber parts for the coaches and wagons The company has also done work for Guinness’s and Cadbury’s in the past. Macsports suppliers over 100 shops nationwide all the handball gear which includes the full range of handballs, the pacer goggles and the Owen & Challenger handball gloves. A small amount of handballs go to Belgium, France, and Holland. Ger Og’s interest in the sport started when he began playing handball in Leixlip and in Ballyfermot and later in Maynooth and Croke Park. Gerry played just for the sheer enjoyment of it. “Ducksie Walsh was the player I remembered first growing up and meeting him several times. It was great being in the presence of a great champion. These days it would be more so Eoin Kennedy I admire” enthused MacCormac |

| Ger Og is very enthusiastic about his job as he involved from the very

beginning to the end. “It is a great for me to be fully involved one week

I maybe involved with the raw materials and the base process, and to see

how we can make it more efficiently. Next week I could be involved

in improving the packaging. And the following week I could be talking

to a new sports distribution outlet. There is great room to improve all

the time. From the raw material until you bring the finished product to

the shop yourself and see it going on the shelves. It is reasonably unique

in that way that you have so much room to get involved in all the different

aspects”.Last year there was a major promotion of children’s handball nationwide.

A joint venture between S.R.C., Macsports and the Irish Handball Council

saw well over 1000 schools throughout the country get a free starter pack,

including posters, stickers, booklets and some free kids balls. The promotion

was a success and has helped introduce more children to handball.

|

|

|

“The future plans for the company would be to maintain the manufacturing

here in Ireland. We are consistently redeveloping the systems to

improve the products and process to cut down on costs. We are always looking

at new products. As well to have our own website where the products

can be ordered on line and we hope to have this up and running shortly,”

explained Gerry.

Irish handball will be indeed in good hands thanks to Macsports, Ger MacCormac & Ger Og. An Irish owned company providing World Class products on the World stage. The company has also been awarded the ISO Manufacturing Standard Organisational award for Excellence Macsports are based in Unit 1, John F.Kennedy Drive, Bluebell, Dublin 12 and Sales Director Ger Og MacCormac can be contacted on 01 4566177. |

| Homage to a ball - Gary McNulty, Frank Semple and Eoin Kennedy | |