Branding Iron

This branding iron was used to brand the horns of cattle. It belonges to Joe Fitzgerald (J.F.). He owned land at Ballyphillip. Kieran Costelloe's father-in-law came up from Waterford with the Fitzgerald family as a herdsman and that is how Kieran got it. Source: - Kieran Costelloe.

Wheel Plough

This is a Ransome wheel plough used by Coadys, Ballyphillip. An interesting thing about this plough is that you can seen two small blades (marked with arrow) at the back of the share. These blades would be turned outwards when ploughing.

In 1947 there were huge falls of snow in February. The snow melted around St.

Patrick's Day causing terrible floods. The land was very wet for weeks and ploughing

and sowing were very late that year. To try to speed up tilling, these blades

were added to help slice up the sod. The blades were made and fitted by a local

blacksmith Mick Kelly at his forge in Seskin.

Source: Tony Coady.

Pair of Thongs

Here are two paris of thongs. The smaller one was used for taking clothes

out of a laundry. The larger one was used for pulling thistles.

Source: Tony Coady.

Potato Masher

It was used for mashing potatoes or turnips in a pigs feeding trough.

Source: Tony Coady.

Dosing Horn

This dosing horn was used by farmers for dosing cattle.

Source: Kieran Costelloe.

Horses

This was used by a harnass maker to hold a saddle, winkers, on any piece of leather steady while he was stitching it. It would be standing upright between his knees with the leather gripped at the top. This left both his hands free for stitching.

Leather was not stitched with a needle and thread as we know it. The holes

for the stitching were made with an "awl". The thread used was called "wax end".

This was hemp thread taht had been rubbed with a black ball of thread. The wax

end was then passed through holes from both sides. This meant there were two

threads in each stich.

Source: Tony Coady.

Stitching

This is a large packing needle (top). It is a very large needle and was used to sew sacks.

This instrument (bottom) was used for marking leather. It was wheeled along

the leather where a harness maker was going to put a line of stitching the teeth

marked the leather at even spaces and this ensured that the stitching would

be even.

Source: Tony Coady.

Ploughing

All ploughing was done by horses. Two horses pulled a "swing plough" or "wheel plough". They ploughed a single furrow. A very good ploughman would plough about an acre in one day. Some people were experts at ploughing and very proud of their work.

Gerry Bergin remembers that Paddy Martin of Inch was an authority on ploughing and sometimes judged ploughing competitions. He also liked to inspect his neighbours' ploughed fields as he passed on his bicycle to see how good their work was.

Pake Bergin, Blackwood remembers winning a County Kilkenny - Under 21 Championship at Birchfield below Kilkenny about 1930. The horses walked there and back that day. Paddy Bergin, Blackwood and Mick McGrath were also known as good ploughmen.

Irish Draught and Clydesdales were the most popular horses. The Irish Draught and a Clydesdales gave a "good honest horse". A good horse would be about 15.3 hands high. It should have plenty of space between the ears. This was a sign of an intelligent horse. It shall also have good legs and feet -" no hoof, no horse".

Horse Inspection

The Irish Government tried to improve the standards of horse breeding. A register

of horses and mares was kept and an owner who wanted a horse or mare registered,

had to have them inspected. This letter to Gerry McCarthy in 1936 told him that

his mare, "Killowen" had passed the inspection.

Source: Lil McCarthy.

Curry Combs

These are two curry combs which were for grooming horses. The one on the left

is very old.

Source: Tony Coady.

Measuring horses

This was used to measure the height of horses. The cross beam was placed over the horse's shoulder and lowered until it touched the withers. The height was read from measurements marked on the upright. Horses are measured in "hands". a hand was about four inches (10cms.).

The Beet Knife

The Beet Knife was a very sharp bladed instrument, measuring 14 inches in length, including the wooden handle, which was held on with rivets. There was a right handed beet knife and a left handed beet knife. To crown beet meant using the knife to remove the green leaves completely. If all the green was not removed, the farmer received a lower price for his beet.

Sugar Beet

Some farmers grew sugar beet. There was plenty of hard work with beet. The beet seed was sown in drills with a machine pulled by a horse. When the beet grew it had to be "thinned". That meant that one beet plant was left every 20 cms. All the other plants and weeds were taken out. This was done by hand while they were crawling on hands and knees along through the drills.

Young children often worked thinning beet and sometimes groups of whole families worked together trying to make a few shillings. It was very hard work for them. They wore sacks tied around their legs. In some fields there were plenty of weeds such as thistles and scutch grass to be pulled and many stones were in the fields.

In the Autumn, the beet was pulled by hand and "crowned", this means that the leaves were cut off with beet knives. The beat was then taken by a horse and cart to the railway station in Ballyragget. Each area had a "beet agent" who worked for the sugar company. The agent in our area was a man named Sgt. Kenny from Ballyconra, (we believe he might have been an ex-R.I.C. Sergent). Later, Paddy White of Ballyconra got this job.

When the sugar factory in Thurles opened, Johnny McCarthy from Graigueswood was the agent for Thurles. The agent would give the farmer a "docket". The docket would set a day when there would be a wagon left at the station in Ballyragget for that farmer's beet. The wagon held 10 tons and he would have to fill it on that day, whatever the weather.

Gerry Bergin remembers Bergins and Farrells working together to fill a wagon. They would each have two horses and carts. They would put "creels" on carts. A cart with creels would hold about one and a quarter tons. Each horse and cart would make two trips to Ballyragget (eight loads altogether to fill a wagon). The carts were unloaded onto the wagon with special beet "sprongs".

The wagon was taken by train, to the factory in Carlow. One person remembers that sometimes there would be a few drinks bought for the men on the carts, at Graces Pub in Ballyragget near the station. They might get bread, butter and lemonade for the boys helping them.

During the Second World War, sugar beet farmers were given a little free sugar to persuade them to have more tillage.

Sugar Beet

This photo was taken about the year 1940, and it includes Daniel Cashin. Thie

group of people are thinning beet in drills. The people at the front are down

on their knees in drills thinning the beet. The two men at the back are using

hoes to thin the beet. They wore bags around their legs to protect themselves.

The bags were tied below the knee and just above the knee.

Source: Elizabeth Doyle.

Killing The Pig

Most farmers kept and killed pigs. James Cuddihy, Tifeaghna, killed pigs for farmers around this area. He would come in the evening to kill and bleed the pig. The next day he would butcher it and salt it. It was then put into a pork barrel.

About two stone of salt was dissolved in a bucket of water and added to the barrel to top it up. The meat jwas then weighed down in the barrel with some heavy stones. The barrel was covered by a canvass bag and a bundle of hay over that. Two pigs would fit in a big barrel. The meat was left in the barrel for about three weeks. It was taken out and left to drip for a day. Then it was hung up in the chimney and smoked.

The meat got very hard while hanging up. It had to be steeped the night before being cooked to soften it and to get rid of some of the salt. People ate very little beef and could have bacon up to 6 days a week. Black pudding was made from the blood of the pig. Sometimes the intestines were filled with a mixture of heart, blood and oaten meal. Brawn could be made by getting the pig's head and some shin beef and boiling it into a jelly.

The Pig Ringer

This implement was used to put rings in the pig's noses to stop them from

rooting in the ground and destroying the fields. They used it by putting the

ring in the implement and closing it on the pigs nose. This was a help for the

farmers who had pigs but it was no fun for the pigs.

Source: Tony Coady.

The Pole Axe

The pole axe was used by a butcher for killing cattle. The cattle were tied down and killed by a blow of the pointed end of the pole axe in the forehead. The other end was used for scraping meat off the bones of the animal.

Churning

Churning or the making of butter, was one of the main chores carried out on farms at the beginning and early part of the century. Women usually carried out the task. Firstly, cows were hand milked. The average farm would have 3 or 4 cows. This milk was then stored in milk crocks which were made of glazed earthenware.

After standing for 12 hours or so, the cream layer would be skimmed. The very skilled and nifty women would be able to tilt the crock in such a way that the cream came away into another container.

Separators

Separators were invented in 1879 by Carl Gustaf de Laval of Sweeden. They are still in the farm business today, supplying milking machines. This made the skimming of milk much more efficient and quicker. A separator consisted of a bowl, 2 outlet pipes, a float and a milk container to feed milk into the bowl.

The bowl was the important part. It was here, the milk was separated. It was made up of a base with a shaft. On the shaft was placed 20 to 24 discs. These were held in place by an outer shell, usually made of heavy metal, while the discs were made of copper. The bowl was then placed on a spindle and would rotate at 1200 r.p.m. when hand-wound.

Milk was drip-fed from the milk container overhead. The flow of milk was controlled by the float. Because the bowl was travelling so fast, instead of falling to the bottom of the bowl, the milk was thrown to the outside.

Separator and Butter Churn

This separator and butter churn were used for butter making. One is an Alfa-Lavel separator and the other is a Diabolo butter churn. The Alfa-Lavel was used to make butter at Delaneys, Ballyphillip. If you read our account of butter making, you can find out how the separator worked. The different constituents of the milk made their way back towards the centre of the bowl through the discs. Cream being the less dense part of the milk, came to the centre and out a separate outlet pipe to the cream bucket. The remainder of the milk called skim milk, came out another vessel. Skim milk was used to feel calves and pigs, part of every farm yard at the time. Today we call this milk low fat milk.

Churns

Most churns were made from oak while most dairy wooden equipment was made from Sycamore.

Making Butter

Milk was collected over a period of days and allowed to stand, or ripen or get sour. Well ripened cream should be smooth, and thick. The churn was first scalded with hot water to open the pores in the timber. It was then scrubbed with salt to purify it, and rinsed with cold water to close pores.

Catherine Quirke, Blackwood said that in the month of May a bunch of white thorn blossoms was picked and placed in the churn with boiling water. This was to purify and remove any stale smells from the churn. The churn was filled about two thirds full with cream, which was diluted at the rate 1 part water to 4 parts cream. In very cold weather, the water used would be slightly warm.

Regardless of the type of churn used, cream had to be agitated between 10-15 minutes before butter granules would appear. The month of May gave best quality. It was much harder to make butter in winter or thundery weather. After churning the buttermilk was removed and used by the people with potatoes as their staple diet. This diet was nutritionally very well balanced.

After removing the butter milk, the butter was washed several times, until the water ran clear. It was then worked on a butter table with a roller and "scotch hands". Some people had a carved crest of timber to stamp the finished block of butter with. After that it was rolled in muslin and large cabbage leaves which were called "cow cabbage".

In warm weather, the butter was then placed in spring wells to keep it cool and hard.

Storing Butter

This churn was manufactured by Waide and Sons, Leeds. It is a Victoria churn

but was known locally as an end-over-end churn. This churn belonged to Ciss

Skehan from Lisdowney. Ciss Skehan was well known for her good quality butter.

The butter was sold as farmer's butter in most local shops. Many other local

people wouldn't buy butter other then from Ciss Skehan's.

Source: Tony Coady.

Butter Making

After churning the butter was washed several times until the water ran clear.

This implement (right) was used for sqeezing the water from the butter. The

butter was then shaped with a pair of scotch hands like the one shown ( left)

on a wooden dish (below).

Source: Tony Coady.

Catherine Quirke from Blackwood remembers that to keep butter for the winter months, it was packed into oak Firkins. These were made by the cooper. When the Firkin was full it would be flanged (made water tight). It would then be buried in a bog.

Pasture

Pasture with wild garlic was not suitable for making butter. Goats were often run with cows to pick up herbs to prevent them tainting butter. Too much clover in pasture or turnips also gave a bad flavour.

Visitors

A visitor was expected to take a hand at the churn or a hand in the dashing. If they did not oblige they would be called a Balor, after Balor of the Evil Eye, one who brought bad luck, and removed the cream from the churn.

Traditions

In the month of May a small piece of unsalted butter was kept. It was mixed with herbs and used to soothe and heal scalds and burns. The old saying was: "Long churning makes bad butter. Butter with a little tear was quality". The tear was a drop of water when cut.

Butter Markets

Before creameries, butter was sold at a weekly market in Kilkenny or to Butter Dealers. The market in Kilkenny was at the back entrance to the market yard at Kytelers Inn. The little lane-way in front of it to High Street is still called "The Butter Slip". The building was a lean too type with timber pillars in front. There were wooden seats where women sat while the butter was sold.

Many of them would have walked long distances. The women from this area, were back home at 11 a.m. after walking home. There were two types of buyers, local housewives and dealers. On the market some people would have regular customers because of their butter. Surplus and lesser quality butter always had difficulty selling.

It was common practice to come along with a spoon to taste the butter before

buying. There was always the crafty customer that got enough by spoon to have

a week's supply. Then there were the butter dealers who were mainly interested

in unsalted butter. They used a sampler which was like an apple corer. It was

pushed into the centre of the butter to check for firmness (no water). This

was their measurement of quality.

Pale Colour - Poor quality, not enough butter milk removed.

Bright Fresh Colour - Good, well washed butter.

The big advantage of dealing in the market was you received cash, while in local shops, it was a barter system in exchange for goods. Women sold their butter to pay part of their grocery bill.

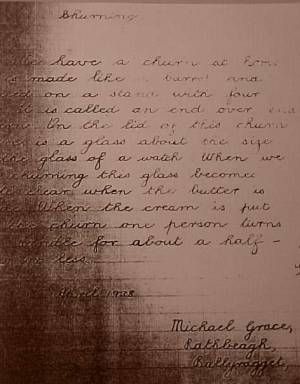

Churning

Mick Grace wrote this piece for the collection of folklore gathered by The

Folklore Commission in 1938. At that time, he was a pupil in Clontubrid National

School.

Source: - Kilkenny County Library.

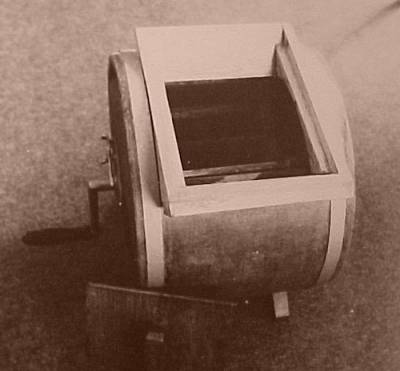

Dutch Churn

This is a Dutch Churn. The paddles were turned by the handle. The cream was

agitated for about fifteen minutes before the butter granules began to appear.

Source: Lily Nolan.

Creameries

Geoff Brennan told us that before 1931, there were two private creameries in Freshford. One of them was called "Cascade Joint Stocks" and was later called "Staunton's". The other creamery was called Mahers. This creamery was started by Butlers and was called "The Old Still Creamery" at one time.

Geoff thinks it was an old distillery once. Later the Government bought out Stauntons to close it down and the hew Co-operative bought Mahers. In those days, an average farmer would have about 8-12 cows. Most farmers had an average 20 gallons of milk a day. A farmer with 20 cows was a big farmer. Milking started every morning at 6.30 or 7.00. The milk was then taken to the creamery by horse and car in large churns. The churns held about 15 gallons. Some people drew milk to the creamery for hire.

They bought back the separated milk to feed the pigs. Milk was about 4d (about 5c) per gallon. When the Co-op started, each farmer had to pay £3 per cow for shares. When the Co-op started most people gave up making their own butter.

Butter Paper

This is a copy of the wrapping paper for butter used by the Co-operative Creamery in Freshford. The trademark was a four leaved shamrock.

Sheep Shears

This was used for shearing when that job was done by hand.

Building a Reek

Mick Grace Building a Reek at Rathbeagh in the 1940s.

Source: - Mick Grace.

Peas

In 1944, Bergins used the engine to thresh peas. Richie Bergin grew an acre of peas for Batchelors, and the acre of peas earned him £100 in that year. The following year he grew 4 acres of peas. They treshed and bagged four and a half tons of peas which were worth £450.

The peas were taken to Cullens Mill, Freshford and dried there. They were then taken to the railway station in Ballyragget. The following year they grew 6 acres of peas but the harvest was very poor because of bad weather. The peas were cut by hand with bill-hooks. In wet years they would be dried on wooden tripods. After a couple of bad years Bergins gave up growing peas.

Guess What?

This unusual intrument was used by people to pack their own Shot gun cartridges.

Source: Tony Coady.

Bull Licences

Most farmers had a bull. All bulls needed a licence and Geoff Brennan remembers that there were two bull inspection days in Freshford. On was in March and the other one was in October. It stayed going from about 1925 till some time in the 1950s. Geoff remembers that a bull licence was 5/=(30c).

The bulls that were to be inspected were brought to Freshford on a given date. There were two inspectors. Bulls that passed were earmarked with a Shamrock. Bulls that failed were stamped with the letter "R". Some farmers kept "scrub bulls" or "speak-easy bulls". A licence inspector looked for these bulls. They went to farmers if there had been a report of an unlicensed bull.

"Cow Doctors"

Thomas Fennelley of Ballring (Geoff Brennan's grandfather) and Martin Moore of Aharney cured animals. Martin Moore had a cure for farsy in horses. The horse's leg would be swollen. He made a cross from woodbine (honeysuckle). He cut the breast of the horse and put in the cross. Then he sewed up the wound.

Paddy Bergin, Blackwood set bones for both animals and people. The broken limb was covered in Burgundy pitch. The pitch was put onto a canvass sheet and this was slapped on hot onto the limb.

Tobacco

In the 1930s, a couple of farmers experimented with growing tobacco. Bergins, Blackwood grew a couple of acres around 1933. When the leaves were pulled they were sewn together on a string with a packing needle. They were hung up in a barn. A couple of farmers built special sheds to cure tobacco. Fires were lit under the leaves to purify the tobacco. The tobacco wasn't very good and the experiment ended.

Turf Compass?

John Kelly told us that he thought that this was a "Turf Compass". It was probably used to mark the distance or the width of the individual's banks of turf.

We were also told it might have been for marking off the "benches"

of thatch on a roof. Any other ideas?

Source: - Kieran Costelloe.